| RP500 | RP1000 | RP2000 | RP3000 | RP6000 | |

|---|---|---|---|---|---|

| Square Drive | 3/4″ | 1″ | 1″ | 1″ | 1″1/2 |

| Min Torque (Nm) | 106 | 201 | 313 | 656 | 968 |

| Max Torque (Nm) | 719 | 1.396 | 2.732 | 4.162 | 8.121 |

| Accuracy | +/-5% | +/-5% | +/-5% | +/-5% | +/-5% |

| Repeatability | 100% | 100% | 100% | 100% | 100% |

| Weight (kg) * | 4,1 | 5,4 | 7,3 | 9,1 | 16,3 |

| MAX Speed (rpm) | 44 | 15 | 9 | 4 | 3 |

| MAX Pressure (bar) | 5,5 | 4,8 | 6,2 | 4,5 | 6,2 |

| Air Consumption (1/min) | 1.557 | 1.557 | 1.557 | 1.557 | 1.557 |

*without reaction arm

| RP500 | RP1000 | RP2000 | RP3000 | RP6000 | |

|---|---|---|---|---|---|

| Square Drive (in) | 3/4″ | 1″ | 1″ | 1″ | 1″1/2 |

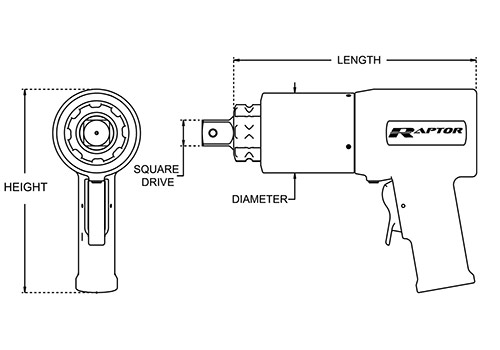

| Height (mm) | 200 | 200 | 200 | 205 | 221 |

| Length (mm) | 173 | 225 | 239 | 295 | 313 |

| Diameter | 65 | 72 | 79 | 95 | 127 |

This arm is designed for socket to socket reaction. The drive/cup design protects the adjacent nut from direct reaction and is adjustable from 100 to 300mm (4″ to 12″).

This arm is designed to accommodate a reaction point at a 90 degree angle from the drive.

This reaction arm is made of raw steel and allows the customer to fabricate their own custom arm. The weld blank is splined to fit the RP Series and includes heat treating specifications.

The RP-FRL Unit is used to filter and lubricate the air supply, as well as regulate the pressure to achieve desired torque output. The unit comes complete with a pressure gauge and 8’ connecting air hose, and is fitted with a one-piece welded steel frame for protection and transport.

The extensions fasten directly to the nose of the tool, allowing for reach into hard to access applications. This works with the standard reaction arm.

This ergonomic handle is durable and allows for left or right hand operation, as well as vertical and horizontal positioning. It can be factory or field installed.

This ergonomic handle is durable and allows for left or right hand operation, as well as vertical and horizontal positioning. It can be factory or field installed.

This ergonomic handle is durable and allows for left or right hand operation, as well as vertical and horizontal positioning. It can be factory or field installed.

For VOLTA and RAPTOR series torque wrenches. Available sizes: from 2″3/16 – 55mm to 3″3/4 – 95mm

The backup wrenches TBW series prevent the opposing nut from turning during the bolting process. They have an ergonomic handle and a quick removal device.

The backup wrenches LTR series prevent the opposing nut from turning during the bolting process. Mechanic removal through a screw.

TorcUP Med s.r.l.

Mediterranean Division of TorcUP Inc. USA

Via del Progresso, 3

20072 FIZZONASCO di Pieve Emanuele (MI)

ITALY

Tel. +39 02 90 42 18 53

Fax +39 02 90 78 29 25

E-mail: info@torcupmed.com

PEC: torcupmed@pec.it

Cod. Destinatario SDI: SUBM70N

P.IVA IT05864680961

Cap. Soc.: €12.345,00 i.v.

TORCUP MED S.R.L. – MEDITERRANEAN DIVISION OF TORCUP INC. USA

Privacy & Cookies Policy